applications of vickers hardness test|how to calculate vickers hardness : purchasing This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests. Ademir jornalista policial Marmita capturada por facção rival. paulo Ataque a escola em Cambé, no Paraná. Kleber Toureiro mexicano sofre escoriações brutais e está em estado grave de saúde. jornalista Ademir ginecologista do Sublime. Empresário é morto a tiros na frente de casa ao sair para buscar encomenda. Osama Bin Laden SUICIDA .

{plog:ftitle_list}

webComo uma colcha de retalhos, Aquaman 2: O Reino Perdido tenta ser maior que seu predecessor misturando muitas coisas, o que nem sempre dá certo. Porém, quando reencontra o tom de aventura do primeiro, ele consegue entreter e se torna uma despedida digna do Snyderverse. Filme que encerra o universo DC de Zack Snyder demora para se .

Find an overview of the Vickers methods and their applications depending on the load range as well as an explanation how to choose the right test load.The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .Exploring the Diverse Applications of Vickers Hardness Testing. 1. Metals and Alloys Industry; 2. Automotive and Aerospace; 3. Manufacturing and Production; 4. Metallurgy; 5. Research and Development; 6. Quality Control and Material .Applications of the Vickers Hardness Test. The Vickers hardness test is used across various industries for different applications. Metallurgy: To determine the hardness of metals & their .

This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests.Regular macro hardness is an application of test when the surface area is large, and the indention is deep. Superficial macro hardness is applied with a large surface area, but penetration is shallow in this test. . The Vickers .

Applications of Vickers Hardness Test. As a result of the relatively minimal indentation produced by the Vickers testing method, its usefulness is extremely important to hardness testing. Application of the Vickers hardness testing .The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, . Since the test indentation is very small in a Vickers test, it is useful for a variety of applications: testing very thin materials like foils or measuring the surface of a part, small parts or small areas, measuring individual .

Single Yarn Strength Tester solution

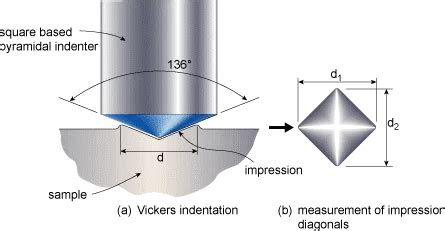

There are several hardness tests available, each designed for specific types of materials & applications, & among them is the Vickers hardness test. Introduction to the Vickers Hardness Test Developed in 1921 by Smith & Sandl & Co. at Vickers Ltd., a British engineering conglomerate, It was initially designed to address the need for a method to .Hardness test method: Static force application: . Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small parts . Hardness is a useful measure of a material’s resistance to permanent indentation; but for viscoelastic polymers, hardness data are highly dependent on the test type and the parameter set chosen. Vickers microhardness testing is used to leave small indents (<150 µm) and is shown to be applicable to polymers. A detailed investigation of the required steps for .Vickers hardness testing to ASTM E92 is a hardness test method with optical evaluation in which the size of the indentation left on the surface of the test material by a pyramid-shaped diamond indenter (square base and interfacial angle of α = 136°) is measured. The test load is applied precisely and the diagonals of the indentations are used to calculate the Vickers .

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it. Hardness, as defined in the first chapter, is a type of resistance to deformation, the roots of which lie in the packing density of atoms and the bonding forces that keep them in place.Application News No. i281 Micro Vickers Hardness Tester Vickers Hardness Test of Curved Surfaces Vickers hardness is used as an index of the mechanical and physical properties of materials in a variety of fields, including quality control at production sites, research andThe reason for these minimum distances is to avoid distortion of the hardness testing results, which could result from the deformation of the material structure. The illustrations below show the minimum distances for the Rockwell (acc. ISO 6508), Brinell (acc. ISO 6506), Vickers (acc. ISO 6507) and Knoop (acc. ISO 4545) methods.Electronic Brinell hardness tester; Digital Brinell hardness tester (touch screen) Visual Brinell hardness tester (touch screen) Fully automatic Brinell hardness tester; Brinell hardness image processing system; Vickers hardness tester series

Discover why the Vickers Hardness Test shines in metallurgy. From microhardness to material diversity, explore when to choose Vickers over other tests. 713-827-0700 . . You want to assess a material’s mechanical properties and suitability for specific applications. When To Choose Vickers Test over a Rockwell Test.

Vickers Hardness Test: This test measures the size of an indentation made on the surface of the material by a diamond pyramid under a specific load. This test is commonly used for thin materials or coatings. . Applications of Hardness Testing. Hardness testing is an essential part of quality control in the manufacturing industry. It is used .

V-Test II Vickers Hardness Tester: For hardness determination on metals and ceramics. The basic set-up includes manually positioned Z-axis on test stand, manually positioned X-axis table magnetic supporting table O 100 mm. The . Vickers hardness tests for the unirradiated and irradiated specimens were carried out at room temperature using a Mitutoyo's HM-200 micro Vickers hardness tester. A load of 0.5 N was employed on the specimen surface to generate Vickers hardness. A hardness datum was measured ten (10) times per a specimen and then an average value was calculated. The Knoop test is particularly suited for very brittle materials or applications requiring precise hardness measurements in small areas, such as the cross-sections of coatings, microstructures, or very thin films, where deeper indentations from the Vickers test might cause cracking or fracture.Experimentation of Micro-Vickers Hardness Test for Composite Nano Materials using DoE 1 Preethi K., 2 Dr. Raju N.T. 1 USN : 1DA15PMJ07, Research Scholar, . The most important application is the production of polymer matrices composites (PMCs), but in last decades an increasing number of metal matrix ones (MMCs) have been presented and .

The indenter employed in the Vickers test is a square-based pyramid whose opposite sides meet at the apex at an angle of 136º. The diamond is pressed into the surface of the material at loads ranging up to approximately 120 kilograms-force, and the size of the impression (usually no more than 0.5 mm) is measured with the aid of a calibrated microscope.

Before diving into conversions, it’s essential to understand how the Vickers and Brinell hardness tests work. 1. Vickers Hardness Test. The Vickers test uses a diamond pyramid-shaped indenter that presses into the material under a specific load. The Vickers hardness value (HV) is determined by measuring the diagonal of the resulting indentation.The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material).Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; Knoop Hardness . tensile strength, yield strength, and ductility, contributing to the manufacturing success. With an immense range of applications, hardness testing forms the backbone of several industries such as automotive, aerospace, and .

The Rockwell hardness test uses a simple mechanical load application, while the Vickers hardness test uses an optical measurement method. The Rockwell hardness test is the most common type of hardness testing method because it is easier to perform and more accurate than other methods.

Brinell hardness test is a method of measuring the hardness of metallic materials which is defined in the ASTM E10 standards. It is used to gauge the hardness and toughness of a material by measuring the depth of an indent left by an indenter on the test piece when it is compressed with a specified load. The advantages of the Vickers hardness test is the extremely accurate readings can be taken and just one type of indenter is used for all types of metals. The Vickers test is capable of testing soft and hard material. The disadvantage of this method is it takes time because the indentation must be measured under the microscope. Besides, the sample must .

Vickers Hardness Test. The Vickers hardness test is performed to measure the hardness of ceramics or other materials by measuring the size of the indentation left by the indenter. It works well for small parts and thin sections. It uses a diamond indenter and a light load to produce an indentation on the material being tested.Vickers number 1 2 Average 1 0 0 0 312. 2 0 0 0 315. 3 0 0 0 317. 4 0 0 0 292. ANALYSIS Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is indicated by a higher HV. Vickers hardness values are a useful tool for comparing the hardness of various materials .

vickers hardness testing procedure

Resultado da 14 de dez. de 2023 · Melhores Horários para Jogar Fortune Rabbit. 1. Manhã cedo. 2. Fim da tarde. 3. Noite tardia. 4. Fins de semana. 5. Feriados. Conclusão. A Hora Certa para Aumentar Suas Chances de Ganhar. 1. Horas de Menor Movimento. 2. Horas de Maior Pagamento. 3. Horas de Bônus. .

applications of vickers hardness test|how to calculate vickers hardness